-

Máquina de embalagem dos malotes

-

Máquina de embalagem do grânulo

-

máquina de embalagem líquida

-

máquina de embalagem do pó

-

Mini Doypack Packaging Machine

-

Máquina de embalagem do saquinho de chá

-

máquina de embalagem do café

-

máquina de embalagem vertical

-

Máquina de embalagem do fluxo

-

Levante-se a máquina de empacotamento do malote

-

Máquina de empacotamento giratória do vácuo

-

Máquina de enchimento

-

Máquina de embalagem horizontal de Doypack

-

Saco de Premade

-

Acessórios da máquina de embalagem

-

Máquina de enchimento e tampa

Máquina Multifuncional de Embalagem de Milho para Alimentos, Vegetais e Frutas, Equipamento de Selagem a Vácuo, Bomba de Enchimento e Rotulagem para Sacos e Bolsas

| Lugar de origem | Guangdong , China |

|---|---|

| Marca | ZCHONE PACK |

| Certificação | ISO,CE |

| Número do modelo | ZC-8200 |

| Quantidade de ordem mínima | 1set |

| Preço | $18000 |

| Detalhes da embalagem | Embalagem de caixa de madeira de exportação padrão |

| Tempo de entrega | 15 |

| Termos de pagamento | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Habilidade da fonte | 1/Sets/15day |

| Tipo | Máquina de embalagem automática | Nome do produto | Máquina de embalagem de várias estacionamentos em grânulos de comida |

|---|---|---|---|

| Dimensão (l*w*h) | L1900*W1400*H1450 | Peso (kg) | 1300 |

| Tensão | 110V 220V 380V 50Hz/60Hz | Capacidade de produção | 20bag/min, 50bag/min, 30bag/min |

| Destacar | máquina de selagem a vácuo para milho,equipamento multifuncional de embalagem de alimentos,máquina de embalagem de grânulos com rotulagem |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Máquina de Embalagem Multifuncional para Milho para Equipamentos de Vedação a Vácuo de Frutas e Vegetais, Bomba de Enchimento e Rotulagem para Sacos e Bolsas

A "máquina de ensacamento a vácuo para milho inteiro" refere-se a um sistema automatizado projetado especificamente para embalar a vácuo, inflar (opcionalmente) e selar espigas de milho inteiras, com ou sem palha.

I. Introdução e Definição do Equipamento

Esta é uma máquina de ensacamento totalmente automática, otimizada e projetada especificamente para produtos longos e de formato irregular, como "milho inteiro".

Alimentação de sacos: Ao contrário das máquinas de embalagem que fazem sacos, este tipo usa sacos pré-fabricados. Um braço robótico remove automaticamente os sacos, os abre, adiciona materiais, faz vácuo, sela e os entrega. Este método oferece estilos de embalagem atraentes e uma variedade de tamanhos de sacos.

Vácuo: Extrai o ar do saco, prolongando significativamente a vida útil do milho e evitando a oxidação e o crescimento microbiano.

Milho Inteiro: Uma vez que o produto alvo é claramente definido, o equipamento será equipado com mecanismos apropriados de carregamento, transporte e posicionamento para acomodar o comprimento e o diâmetro do milho.

II. Fluxo de Trabalho Principal

Ensacamento: Um braço robótico extrai automaticamente um saco pré-fabricado (geralmente um saco a vácuo composto de nylon/PE) do armazenamento de sacos.

Abertura do Saco: Uma garra ou ventosa abre com precisão o saco e o prepara para alimentação.

Alimentação:

Alimentação manual: Um operador coloca manualmente o milho pré-processado (geralmente cozido e resfriado) no saco aberto. Este é o método mais comum e econômico.

Alimentação automatizada: Uma correia transportadora dedicada e um braço robótico alimentam o milho no saco de forma automática e precisa. Maior grau de automação, mas equipamento mais complexo e custos mais altos.

Vácuo e Selagem:

A abertura do saco é transportada sob a tampa da câmara de vácuo e pressionada com segurança.

A bomba de vácuo é ativada para remover o ar do saco.

(Opcional) Inflação: Se um "pacote preenchido a vácuo" for desejado (por exemplo, nitrogênio é adicionado para manter melhor a forma e evitar o esmagamento), um gás inerte é injetado durante esta etapa.

Após o vácuo/inflação, um dispositivo de selagem térmica aquece e pressuriza a abertura do saco para selá-lo.

Resfriamento e Entrega: Após a selagem, a abertura do saco é resfriada para definir sua forma, e o saco finalizado é então transportado para fora do equipamento, completando o processo de embalagem.

III. Principais Vantagens

Preservação da Frescura Altamente Eficaz: O vácuo inibe efetivamente o crescimento de bactérias aeróbicas, evitando a perda de umidade e sabor no milho. A oxidação prolonga significativamente a vida útil.

Qualidade do Produto Aprimorada: A embalagem a vácuo cria uma aparência limpa e atraente para os produtos, facilitando a impressão de branding requintado e informações do produto no saco, aumentando o valor agregado.

Alto Nível de Automação: Em comparação com a embalagem a vácuo manual, a eficiência é aumentada várias ou dezenas de vezes, economizando mão de obra significativa e reduzindo custos a longo prazo.

Embalagem Segura: A selagem térmica oferece forte força de selagem e uma estanqueidade superior, com uma taxa de vazamento de ar muito menor do que a embalagem manual.

Flexibilidade: Ao substituir as mandíbulas e o molde, a máquina pode acomodar milho de vários tamanhos e sacos de embalagem, permitindo múltiplos usos.

IV. Produtos e Aplicações Aplicáveis

Produtos:

Milho Fresco Embalado a Vácuo

Milho Cozido Embalado a Vácuo (Mais Comum)

Milho Preenchido com Nitrogênio Embalado a Vácuo

Especificação da Máquina:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Embalagemvelocidade | MÁX 60 sacos/min, dependendo da qualidade do filme de embalagem, materiais de embalagem, peso da embalagem, etc. | ||

| Tamanho do saco | (C)100-300mm (L)70- 200mm | (C)100-350mm (L)130- 250mm | (C)150-450mm (L)200-300mm |

| Tipo de saco | Sacos pré-fabricados, saco vertical, saco selado nos quatro lados, saco selado nos três lados saco, saco de formato especial | ||

| Faixa de pesagem | 10g-1kg | 10g-2kg | 10g-3kg |

|

Medição precisão |

*≤±0,5~1%, dependendo do equipamento de medição e materiais. | ||

| Largura máxima do saco | 200mm | 250mm |

300mm |

| Consumo de gás | 0,8Mpa 0,3m3/min (Fornecido pelo usuário) | ||

| Total Potência/Tensão | 2,5KW 380V 50/60Hz | 2,5KW 380V 50/60Hz | 3,7KW 380V 50/60Hz |

| Compressor de ar | Não menos que 1CBM | ||

| Dimensão | C1900*L1400*A1450 | C1900*L1400*A1450 | C2000*L1500*A1550 |

| Peso da Máquina | 1300kg | 1400kg | 1500kg |

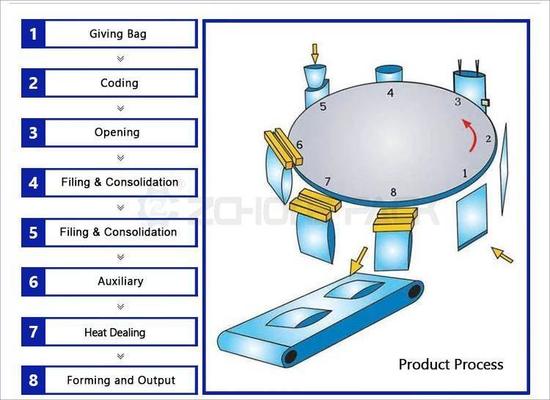

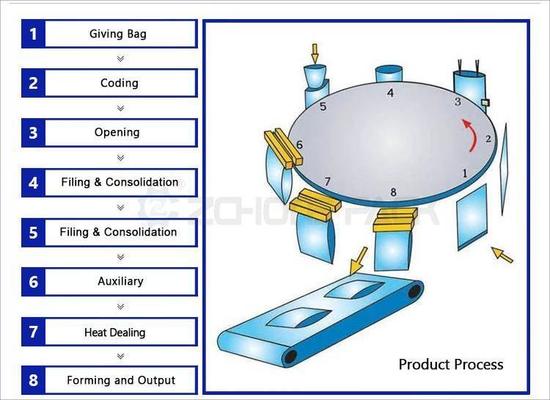

| Fluxo de trabalho | Dar saco→Codificação→Abrir saco (ou Abrir saco com zíper)→Enchimento→ Auxiliar→Exaustão→Selagem térmica→Formação e saída de produtos. | ||

| Escopo aplicável | Tipo granular: glutamato monossódico cristalino, medicamento granular, cápsula, sementes, produtos químicos, açúcar, essência de frango, sementes de melão, nozes, pesticidas, fertilizantes, etc. | ||

(Podemos fornecer serviços personalizados exclusivos de acordo com suas necessidades!)

![]()

![]()

![]()

![]()