-

Máquina de embalagem dos malotes

-

Máquina de embalagem do grânulo

-

máquina de embalagem líquida

-

máquina de embalagem do pó

-

Mini Doypack Packaging Machine

-

Máquina de embalagem do saquinho de chá

-

máquina de embalagem do café

-

máquina de embalagem vertical

-

Máquina de embalagem do fluxo

-

Levante-se a máquina de empacotamento do malote

-

Máquina de empacotamento giratória do vácuo

-

Máquina de enchimento

-

Máquina de embalagem horizontal de Doypack

-

Saco de Premade

-

Acessórios da máquina de embalagem

-

Máquina de enchimento e tampa

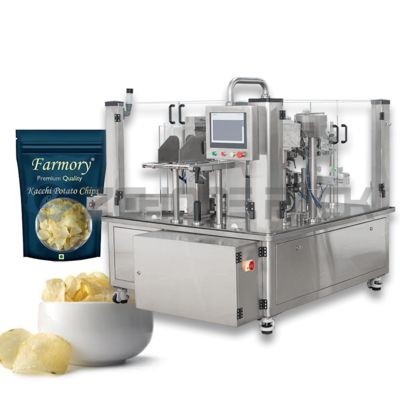

Máquina de embalagem de chips de batata para sacos pré-fabricados multifuncionais, eficazes em vácuo e preenchidos com nitrogênio, para alimentos inflados

| Lugar de origem | Guangdong , China |

|---|---|

| Marca | ZCHONE PACK |

| Certificação | ISO,CE |

| Número do modelo | ZC-8200 |

| Quantidade de ordem mínima | 1set |

| Preço | $18000 |

| Detalhes da embalagem | Embalagem de caixa de madeira de exportação padrão |

| Tempo de entrega | 15 |

| Termos de pagamento | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Habilidade da fonte | 1/Sets/15day |

| Tipo | Máquina de embalagem automática | Nome do produto | Máquina de embalagem de várias estacionamentos em grânulos de comida |

|---|---|---|---|

| Dimensão (l*w*h) | L1900*W1400*H1450 | Peso (kg) | 1300 |

| Tensão | 110V 220V 380V 50Hz/60Hz | Capacidade de produção | 20bag/min, 50bag/min, 30bag/min |

| Destacar | máquina de embalagem de batatas fritas com enchimento de nitrogénio,Máquina de embalagem de grânulos eficaz a vácuo,Máquina de embalagem de alimentos multifuncional |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Máquina de Embalagem de Batatas Fritas para Sacos Pré-fabricados Multifuncionais, Eficazes a Vácuo e Preenchidos com Nitrogênio para Alimentos Inflados

Uma "máquina de embalagem de batatas fritas com sacos pré-fabricados" é um equipamento muito comum e crítico na indústria de embalagens de alimentos. Refere-se a uma máquina automatizada que utiliza sacos pré-fabricados e pré-impressos (ou seja, sacos pré-fabricados) para pesar, encher e selar batatas fritas.

I. O que é uma máquina de embalagem de batatas fritas com sacos pré-fabricados?

Ao contrário de uma máquina de embalagem "form-fill-seal", uma máquina de embalagem com sacos pré-fabricados não fabrica os próprios sacos. Em vez disso, utiliza sacos com três ou quatro selagens laterais já produzidos por um fabricante profissional de sacos. As vantagens deste método de embalagem são:

Embalagem bonita: Os sacos pré-fabricados normalmente utilizam técnicas de impressão de alta qualidade (como impressão em rotogravura), resultando em designs mais vibrantes e complexos.

Alta velocidade de embalagem: Como a fabricação de sacos no local é eliminada, a velocidade de embalagem é normalmente maior, tornando-a adequada para produção em larga escala.

Vários tipos de sacos: Estas máquinas podem acomodar uma variedade de tipos de sacos especiais, incluindo sacos stand-up, sacos com zíper e sacos com formatos personalizados.

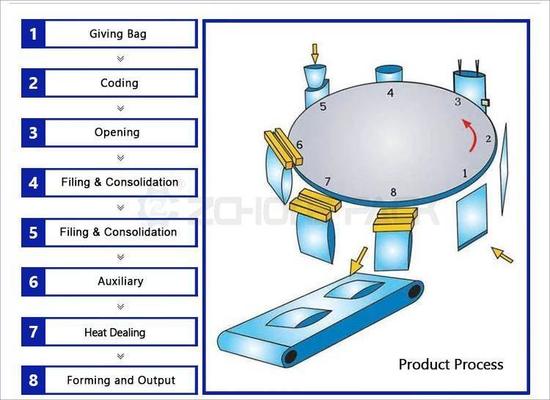

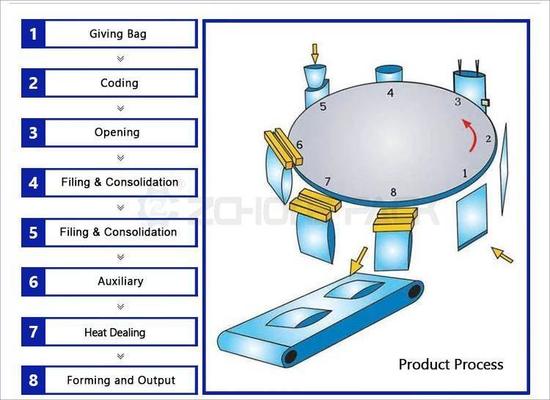

II. Fluxo de Trabalho Principal

Uma máquina de embalagem de batatas fritas com sacos pré-fabricados típica opera da seguinte forma:

Ensacamento: Um braço robótico ou dispositivo de ventosa remove com precisão um saco pré-fabricado do armazenamento de sacos.

Abertura do saco: Uma pinça agarra a abertura do saco em ambos os lados e abre-o usando ar comprimido ou ventosas.

Enchimento: Simultaneamente com a abertura do saco, um pesador combinacional multicabeças a montante pesa com precisão as batatas fritas até um peso especificado.

As batatas fritas são despejadas de forma rápida e precisa no saco aberto através de um funil de enchimento.

Desgaseificação: Antes da selagem, a máquina remove o excesso de ar do saco por meio de vibração ou compressão para evitar o esmagamento das batatas fritas durante o transporte e manter uma embalagem plana.

Selagem: Uma seladora térmica aquece e pressuriza a abertura do saco para completar a selagem. Para sacos com zíper, o zíper também é selado primeiro.

Modelagem e Saída: Após a selagem, o saco é liberado e transportado por uma correia transportadora. Também pode passar por dispositivos de resfriamento e modelagem para obter uma aparência mais crocante.

Inspeção e Rejeição: Durante todo o processo, um sistema de inspeção visual pode verificar se a abertura do saco está totalmente aberta, se a selagem está intacta e se a data/número do lote está legível. Os produtos não qualificados são rejeitados automaticamente.

III. Componentes Principais do Equipamento

Mecanismo Automático de Ensacamento: Responsável pela alimentação estável e de alta velocidade de sacos pré-fabricados.

Dispositivo de Abertura de Saco: Garantir a abertura confiável do saco a cada vez é fundamental para a eficiência.

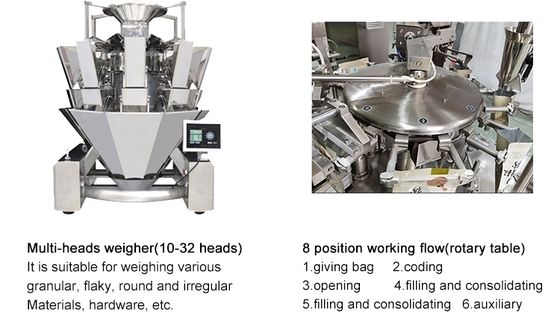

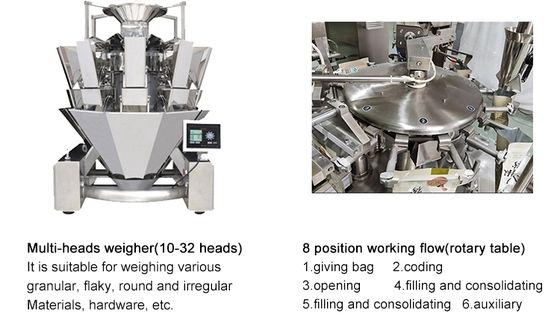

Pesador Combinacional Multicabeças: Um dos "cérebros" da máquina de embalagem, utiliza vários funis de pesagem para obter pesagem de alta precisão em altas velocidades.

Sistema de Enchimento: Guia as batatas fritas para dentro do saco, reduzindo detritos e poeira.

Sistema de Selagem Térmica: O atuador principal, cuja temperatura, pressão e controle de tempo impactam diretamente a qualidade da selagem.

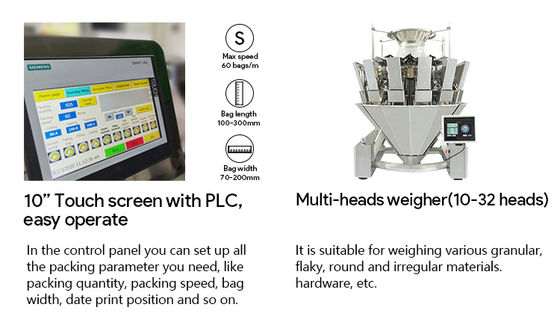

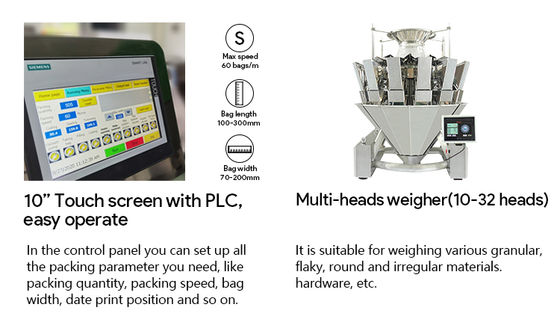

Sistema de Controle PLC: O sistema nervoso central de todo o equipamento, coordenando a operação de vários componentes e permitindo que o operador defina parâmetros.

Sistemas de Inspeção: Esses sistemas, como verificadores de peso, detectores de metais e sistemas de inspeção visual, são usados para controle de qualidade e segurança do produto.

IV. Principais Características e Vantagens

Alta Precisão: O pesador combinacional normalmente atinge uma precisão de pesagem de ±0,5-1 grama.

Alta Eficiência: Uma ampla gama de velocidades está disponível, variando de dezenas a centenas de sacos por minuto, dependendo do número de estações de trabalho e do grau de automação.

Flexibilidade: Ao substituir a garra e o molde, pode acomodar sacos pré-fabricados de vários tamanhos e formatos.

Alta Automação: Todo o processo, desde a remoção do saco até a entrega do produto acabado, é totalmente automatizado, reduzindo significativamente o trabalho manual.

Excelente Vida Útil: Um sistema de descarga de nitrogênio remove o ar do saco antes da selagem, reabastecendo-o com nitrogênio para prolongar efetivamente a vida útil das batatas fritas e evitar que sejam esmagadas.

Especificação da Máquina:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Embalagemvelocidade | MÁX 60 sacos/min, dependendo da qualidade do filme de embalagem, materiais de embalagem, peso da embalagem, etc. | ||

| Tamanho do saco | (C)100-300mm (L)70- 200mm | (C)100-350mm (L)130- 250mm | (C)150-450mm (L)200-300mm |

| Tipo de saco | Sacos pré-fabricados, saco stand-up, saco selado nos quatro lados, saco selado nos três lados saco, saco com formato especial | ||

| Faixa de pesagem | 10g-1kg | 10g-2kg | 10g-3kg |

|

Medição precisão |

*≤±0,5~1%, dependendo do equipamento de medição e materiais. | ||

| Largura máxima do saco | 200mm | 250mm |

300mm |

| Consumo de gás | 0,8Mpa 0,3m3/min (Fornecido pelo usuário) | ||

| Total Potência/Tensão | 2,5KW 380V 50/60Hz | 2,5KW 380V 50/60Hz | 3,7KW 380V 50/60Hz |

| Compressor de ar | Não menos que 1CBM | ||

| Dimensão | C1900*L1400*A1450 | C1900*L1400*A1450 | C2000*L1500*A1550 |

| Peso da Máquina | 1300kg | 1400kg | 1500kg |

| Fluxo de trabalho | Dar saco→Codificação→Abrir saco (ou Abrir saco com zíper)→Enchimento→ Auxiliar→Exaustão→Selagem térmica→Formação e saída de produtos. | ||

| Âmbito aplicável | Tipo granular: glutamato monossódico cristalino, medicamento granular, cápsula, sementes, produtos químicos, açúcar, essência de frango, sementes de melão, nozes, pesticidas, fertilizantes, etc. | ||

(Podemos fornecer serviços personalizados exclusivos de acordo com suas necessidades!)

![]()

![]()

![]()

![]()