-

Máquina de embalagem dos malotes

-

Máquina de embalagem do grânulo

-

máquina de embalagem líquida

-

máquina de embalagem do pó

-

Mini Doypack Packaging Machine

-

Máquina de embalagem do saquinho de chá

-

máquina de embalagem do café

-

máquina de embalagem vertical

-

Máquina de embalagem do fluxo

-

Levante-se a máquina de empacotamento do malote

-

Máquina de empacotamento giratória do vácuo

-

Máquina de enchimento

-

Máquina de embalagem horizontal de Doypack

-

Saco de Premade

-

Acessórios da máquina de embalagem

-

Máquina de enchimento e tampa

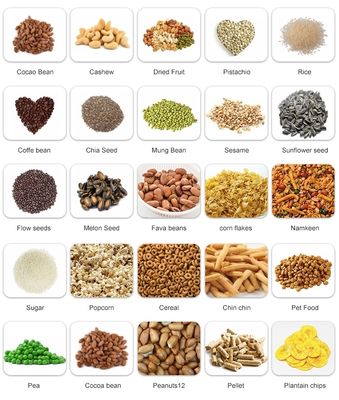

Máquina de Embalagem de Alimentos Totalmente Automática Multifuncional para Nozes, Batatas Fritas, Biscoitos, Doces, Amendoins, Feijão e Arroz

| Lugar de origem | Guangdong , China |

|---|---|

| Marca | ZCHONE PACK |

| Certificação | ISO,CE |

| Número do modelo | ZC-8200 |

| Quantidade de ordem mínima | 1set |

| Preço | $18000 |

| Detalhes da embalagem | Embalagem de caixa de madeira de exportação padrão |

| Tempo de entrega | 15 |

| Termos de pagamento | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Habilidade da fonte | 1/Sets/15day |

Contacte-me para amostras grátis e vales.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Se você tem algum interesse, nós fornecemos a ajuda online de 24 horas.

x| Tipo | Máquina de embalagem automática | Nome do produto | Máquina de embalagem de várias estacionamentos em grânulos de comida |

|---|---|---|---|

| Dimensão (l*w*h) | L1900*W1400*H1450 | Peso (kg) | 1300 |

| Tensão | 110V 220V 380V 50Hz/60Hz | Capacidade de produção | 20bag/min, 50bag/min, 30bag/min |

| Destacar | Máquina de embalagem de alimentos totalmente automática,máquina de embalagem de grânulos para nozes,máquina de embalagem multifuncional para salgadinhos |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Máquina de Embalagem de Alimentos Totalmente Automática Multifuncional para Nozes, Batatas Fritas, Biscoitos, Doces, Amendoins, Feijão e Arroz

A "Máquina de Embalagem de Nozes Ensacadas" é um equipamento altamente especializado usado na indústria de processamento de alimentos.

I. Introdução à Máquina de Embalagem de Nozes Ensacadas

Uma máquina de embalagem de nozes ensacadas é uma máquina automatizada ou semiautomatizada projetada especificamente para encher e selar várias nozes (como nozes, amêndoas, castanhas de caju, nozes macadâmia e amendoins) em sacos de acordo com pesos predefinidos. Ela melhora significativamente a eficiência da produção, garante a qualidade da embalagem e os padrões higiênicos, e é uma peça central de equipamento para empresas modernas de processamento de nozes.

II. Tipos Principais

Com base no grau de automação e formato da embalagem, essas máquinas são principalmente categorizadas da seguinte forma:

1. Máquina de Embalagem de Saco Stand-Up

Princípio de Funcionamento: Ensacamento, enchimento e selagem no local são realizados usando filme em rolo. Começando com um rolo de filme de embalagem, um formador o transforma em um tubo, selando as bordas longitudinalmente. Um mecanismo de selagem transversal então sela a parte inferior, enchendo o saco com o produto e, finalmente, selando e cortando o saco no topo para formar um saco completo.

Vantagens: Uma variedade de estilos de embalagem (como selagem traseira, selagem de três lados e selagem de quatro lados) estão disponíveis, o espaço é economizado e as trocas de material são flexíveis.

Aplicação: Adequado para embalagens de pequeno tamanho (alguns gramas a 1 quilograma) de nozes pequenas e médias (como amendoins, sementes de melão e amêndoas).

2. Máquina de Embalagem com Alimentação de Saco

Princípio de Funcionamento: Usando sacos pré-fabricados, a máquina remove automaticamente os sacos, os abre, os enche com o material e, em seguida, os sela (por exemplo, selagem a quente, selagem com linha ou selagem com zíper).

Vantagens: Oferece uma variedade de formatos de saco atraentes (como sacos stand-up, sacos com zíper e sacos com formatos personalizados), implementa facilmente o enchimento com nitrogênio para preservação do frescor e é rápido.

Aplicação: Adequado para embalagens de vários tamanhos e tipos de sacos, especialmente para produtos de nozes de alta qualidade que exigem enchimento com nitrogênio para preservação do frescor.

3. Classificação do Método de Pesagem

Pesagem com um único funil: Estrutura simples e baixo custo, mas velocidade lenta e precisão média.

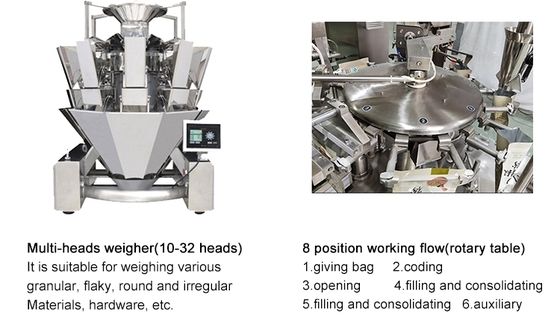

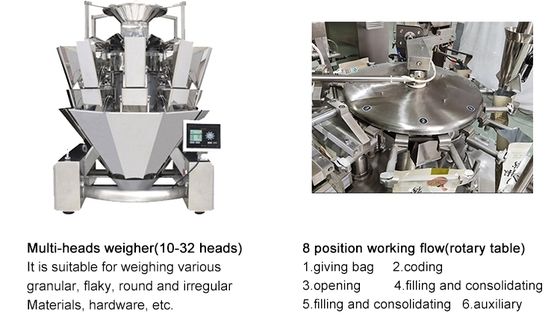

Pesador de combinação (pesador de combinação de computador multi-cabeça): Consiste em vários funis de pesagem. Um computador calcula os pesos dos vários funis e os combina para obter a combinação mais próxima do peso alvo para enchimento.

Vantagens: Precisão extremamente alta (até ±0,1-1 grama) e alta velocidade, tornando-o a escolha principal e de alta precisão para embalagem de nozes.

Aplicável a: Todas as linhas de embalagem automatizadas com requisitos rigorosos de peso.

III. Componentes Essenciais

Uma máquina de embalagem de nozes ensacadas completa normalmente inclui os seguintes sistemas:

Sistema de Carregamento: As nozes são transportadas para o funil de armazenamento da máquina de embalagem por meio de um elevador, placa vibratória ou correia transportadora.

Sistema de Pesagem: O componente principal, como uma balança de combinação ou balança de funil único, é responsável por medir com precisão o peso de cada saco.

Sistema de Formação e Enchimento de Saco (Máquina Vertical) ou Sistema de Abertura de Saco (Alimentador de Saco): Completa a formação ou preparação do saco.

Sistema de Enchimento com Nitrogênio (Opcional): Antes da selagem, o saco é desaerado e preenchido com nitrogênio para prolongar a vida útil das nozes e evitar a oxidação do óleo.

Sistema de Selagem a Quente: Um elemento de aquecimento sela a abertura do saco.

Sistema de Codificação: Imprime informações como a data de produção e o número do lote no saco.

Sistema de Controle: Um CLP (Controlador Lógico Programável) e uma interface homem-máquina com tela sensível ao toque são usados para definir parâmetros, controlar todo o processo e monitorar o status operacional.

IV. Resumo e Recomendações

Pequenas Empresas/Marcas Iniciantes: Comece com uma máquina de embalagem semiautomática (colocação manual do saco, pesagem e enchimento da máquina) ou uma máquina de embalagem com pesador de combinação vertical básico. Elas oferecem baixo investimento e alta flexibilidade.

Empresas de Médio e Grande Porte: Recomendamos máquinas de embalagem com alimentação de saco totalmente automáticas ou máquinas de embalagem verticais de alta velocidade, equipadas com pesadores de combinação e capacidades de enchimento com nitrogênio, para atender às necessidades de produção de alto volume, alta qualidade e longa vida útil.

Linha de Produtos de Alta Qualidade: As máquinas de embalagem com alimentação de saco e enchimento com nitrogênio são a escolha preferida, proporcionando a aparência de embalagem mais bonita e a preservação ideal do frescor.

Especificação da Máquina:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Velocidade deembalagem | MÁX 60 sacos/min, dependendo da qualidade do filme de embalagem, materiais de embalagem, peso da embalagem, etc. | ||

| Tamanho do saco | (C)100-300mm (L)70- 200mm | (C)100-350mm (L)130- 250mm | (C)150-450mm (L)200-300mm |

| Tipo de saco | Sacos pré-fabricados, saco stand-up, saco selado nos quatro lados, saco selado nos três lados saco, saco com formato especial | ||

| Faixa de pesagem | 10g-1kg | 10g-2kg | 10g-3kg |

|

Precisão da medição |

*≤±0,5~1%, dependendo do equipamento de medição e materiais. | ||

| Largura máxima do | saco | 200mm |

250mm |

| 300mm | Consumo degás 0,8Mpa 0,3m | ||

| 3 | Potência/Tensão | Potência/Tensão | total |

| 2,5KW 380V 50/60Hz | 2,5KW 380V 50/60Hz | ||

| 3,7KW 380V 50/60Hz | Não menos que 1CBM | Não menos que 1CBM | Dimensão |

| C1900*L1400*A1450 | C1900*L1400*A1450 | C2000*L1500*A1550 | Peso da máquina |

| 1300kg | 1400kg | ||

| 1500kg | Fluxo de trabalho | ||

Dar saco→Codificação→Abrir saco (ou Abrir saco com zíper)→Enchimento→ Auxiliar→Exaustão→Selagem a quente→Formação e saída de produtos.

![]()

![]()

![]()

![]()